Metal Fabrications - Press brake forming

Accuracy, Accuracy, Accuracy that is what we do, and when it comes to our forming capabilities, there is no doubt that we have always had the best equipment to meet your needs, and 2020 is no different. We’ve entered the new year with the latest press brake technology that Amada has to offer. The new breed of Amada HG press brakes has automatic angle measurement systems and material thickness detection. This feature provides internal measuring integration at the point of production and helps ensure we’re making parts accurately. The interface on the HG machines comes via a 19” smartphone-style control unit, and with all of our machines utilizing the same interface, it makes for a seamless cross-utilization by our floor staff. We’ve always been a company wanting to lead rather than follow the industry. We took a leap forward by becoming the first company in North America to have the Amada HG1003 AR bending robot back in 2016. This machine is programmed virtually in engineering, and with a transfer of information, it’s operating robotically, setting itself up and forming parts. We will continue to provide the latest technology in producing your parts and strive to maintain our high customer satisfaction scores, our low DPPM numbers, and the highest of on-time delivery scores. We have no prolonged setups; things are accomplished rapidly and efficiently, which saves us time and provides our customers with a lower cost. The equipment in our forming area is dialed in and ready to meet your needs.

Amada HG 1703NT PRESS BRAKE

The HG 1703 is a 170 ton, down acting, servo/hydraulic hybrid press brake with a bed length of 10 feet. This super accurate, high-speed 9-axis machine reduces the positioning time, and effortlessly handles the staging of an intricate part. This HG 1703 has the added benefit of having “Sheet Followers.” This option improves accuracy and safety by assisting operators when having to handle large and heavy parts. Our Dr.ABE Bend off-line programming software further increases the high productivity offered by the HG 1703 press brake.

Amada HG 1303 Press Brake

The HG 1303 is a 130 ton, down acting, servo/hydraulic press brake with a bed length of 10 feet. This super accurate, high-speed 9-axis machine reduces the positioning time and easily handles staging of a complex part. Our Dr.ABE Bend off-line programming software further increases the high productivity offered by the HG 1303 press brake.

AMADA HG 8025 PRESS BRAKE

The HG 8025 is an 88 ton, down acting, servo/hydraulic press brake with a bed length of 8 feet. Equipped with:

AMNC-3i Control: An advanced control system with a 19-inch multi-touch LCD panel for intuitive operation.

6-Axis Back-Gauge: Enhances setup precision.

Laser Safety Curtains, Foot Pedal, and Bend Angle Sensor for safety and efficiency.

The HG 8025 combines speed, accuracy, and ease of use, making it an excellent choice for precision bending tasks

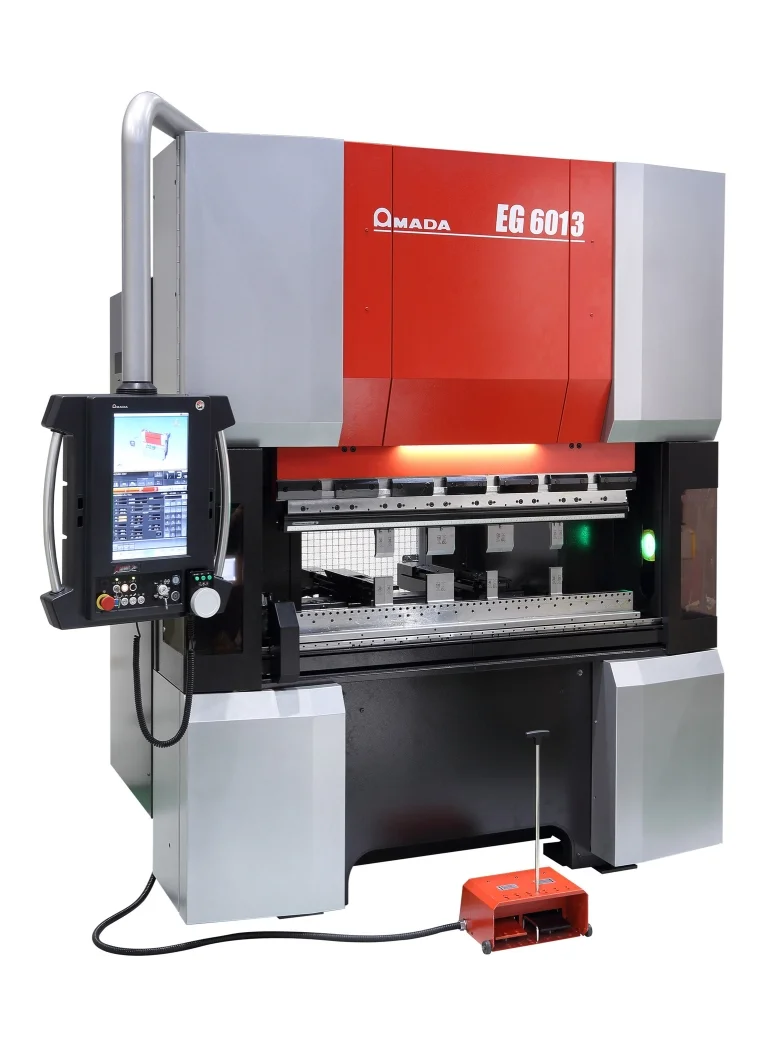

AMADA EG 6013 PRESS BRAKE

The EG 6013 is an ultra-high precision, high-speed compact press brake designed for bending sheet metal components. Here are some key features:

Dual Servo Power (DSP) Drive System: The EG utilizes two AC-servo motors, enabling extremely fast approach, bending, and return speeds. Which results in faster cycle times and more parts produced per hour.

AMNC 3i Control: The 18.5-inch multi-touch display offers various modes of data entry (angle, depth, 2D, and 3D), providing programming flexibility.

L-Shift Back-Gauge: The 5-axis back gauge speeds up setup for complex parts. High-speed movement ensures precise positioning of gauge fingers.

Overall, with a maximum bed length of 53", the EG 6013 delivers fast, accurate bending for highly automated workflows

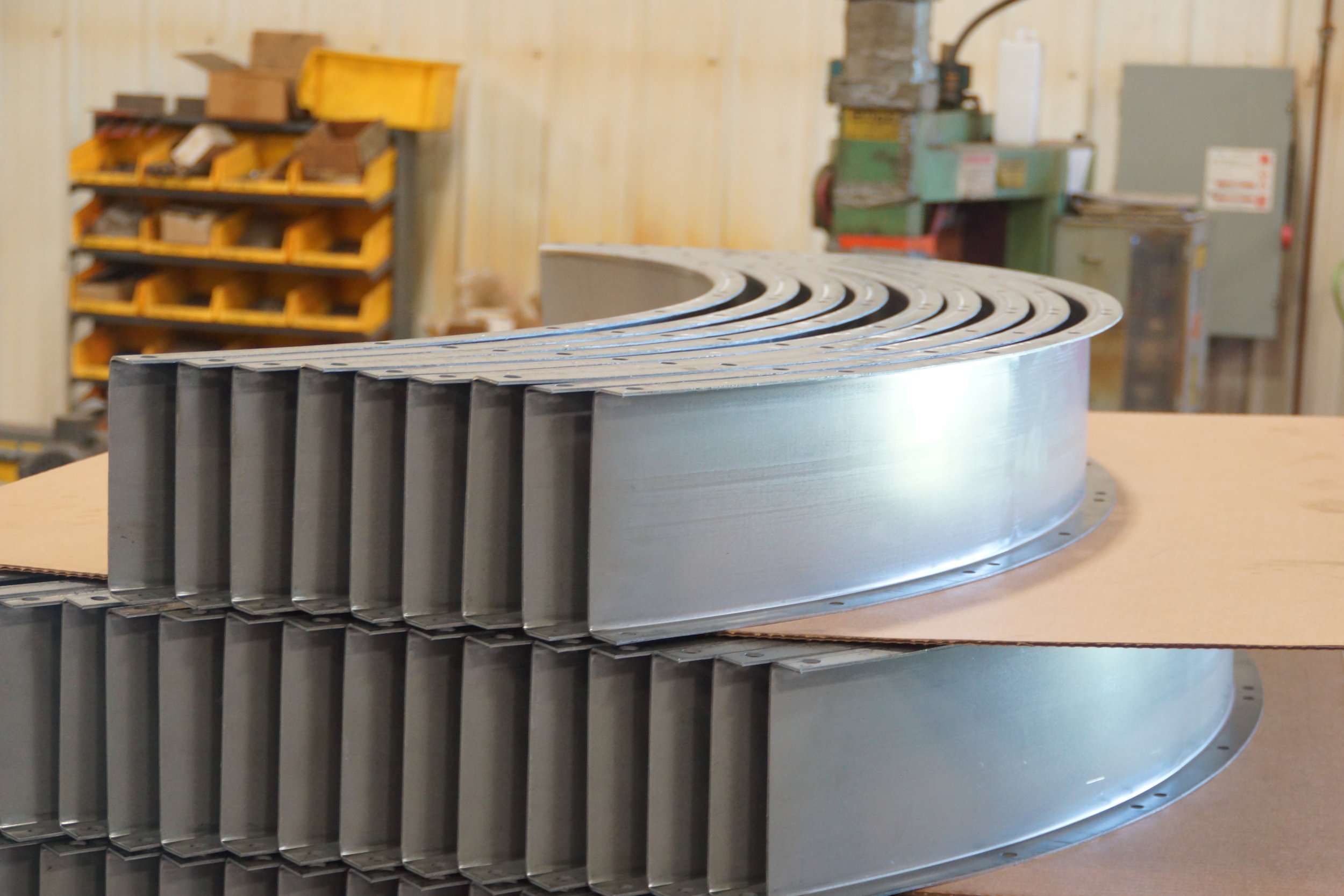

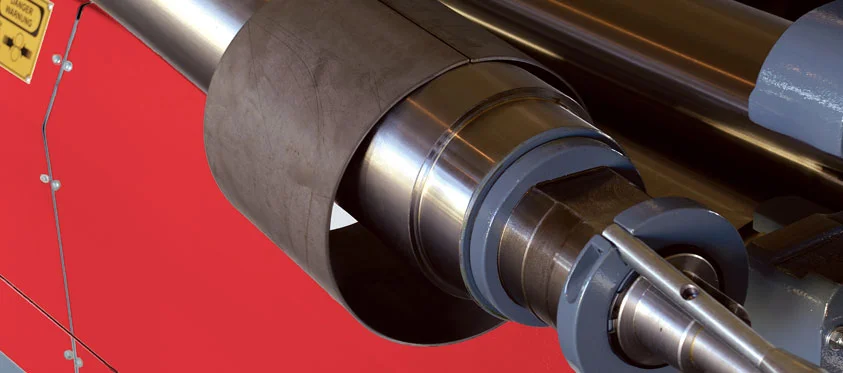

JMT HRB4 1504 plate and Shape roller

The JMT HRB4 is an accurate and reliable CNC controlled roller that can meet your needs for rolled parts. Plates and shapes are no problem with this machine, the capacity sizes are 60" and 5/32" mild steel thickness.